10 Different Types of Jacks & Their Uses (With Pictures)

-

- Last updated:

For instance, a floor jack can work great for lifting a car, but a semi-truck needs a bottle jack. Why? And why invest in a floor jack when a cheap steel scissor jack works just fine? There is a method to the madness, and often, it has to do with preference and convenience. But sometimes, it is all about safety.

The 10 Types of Jacks & Their Uses

Let’s get familiar with the variations of this fantastic tool.

1. Scissor Jack

The scissor jack is the simplest type and comes standard with many smaller cars. Instead of hydraulic pressure, it uses a screw mechanism. It is small and portable, capable of fitting in a small space, and is one of the main types of car jacks. Traditionally, there is a marked area where this will fit when lifting your vehicle.

Uses

- Changing tires

- Minor vehicle maintenance and repairs

2. Floor Jack

The floor jack is the common jack most people see, and it’s perfect for auto repairs because of its low-profile design. It is probably the most popular car jack. It can be rolled on heavy steel wheels to any point under the car, and the long pump handle raises the jack, lifting the vehicle. This uses hydraulic pressure and has a release valve on the top of the handle on most models. You may find it useful for some light construction projects such as installing a staircase.

Uses

- Great for high-ground clearance vehicles

- Vehicle and equipment maintenance and repairs

- Light construction projects

3. Bottle Jack

Another hydraulic jack, the bottle jack is also a common fixture in automotive work. It can have a pump handle and/or an air compressor attachment, and its only flaw is its size and shape doesn’t really work with low-profile vehicles. Depending on the model, these can lift between four and 50 tons.

Uses

- Automotive repairs

- Some high-clearance equipment maintenance

- Medium to heavy construction projects

4. Pneumatic Jack

Uses

- Heavy machinery

- Construction work

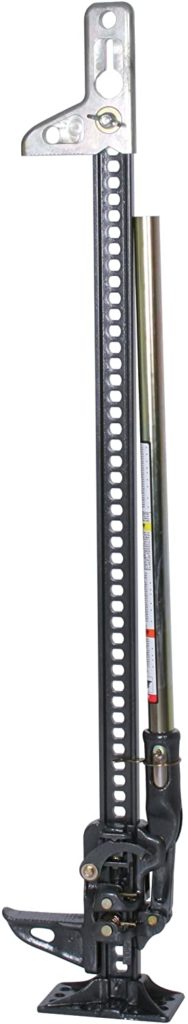

5. Hi-lift Jack

If you love off-roading, you might have seen a hi-lift jack once or twice. Also known as a farm jack, these are employed when lifting a vehicle out of the mud or when a wench is needed. These are rated to 7,000 pounds and can lift a car up to five feet off the ground.

Uses

- Off-road vehicle lifting

- Farm equipment maintenance

- Wenching

6. Strand Jack

If it needs a heavy-duty lift, a strand jack is ready to work. These are commonly used in construction and engineering and are capable of lifting bridges, power stations, and other larger, heavier, items.

Uses

- Heavy-duty lifting

- Construction and engineering

7. Trolley Jack

Uses

- Automotive repairs

- Some high-clearance equipment maintenance

- Medium to heavy construction projects

8. Motorcycle Jack

Because of their small, low-profile engines, working on motorcycles can be tricky. A motorcycle jack is employed to lift the entire unit of the ground, giving easy access to critical parts. It can also be used for ATVs, and with modification, snowmobiles.

Uses

- Motorcycle repairs

- ATV and snowmobile maintenance

9. Forklift (Pallet) Jack

Also known as a pallet jack, this style operates in a similar capacity as a floor jack and bottle jack if combined. It has a steel handle, is elevated in design, and the push rod is quite a bit longer than the standard bottle jack. It can handle up to 8,800 pounds with ease.

Uses

- Warehouse

- Shipping and receiving

10. Hydraulic (Mechanical Service) Jack

Uses

- Trailers (boat and hauling)

- Recreational vehicles

Picking the Right Jack

If you are planning to invest in a new jack or buying one for a friend who complains about not having one, the application is key to the style you get, as well as its source of power. And by power, we mean the hydraulic pressure used to push the rod out of its sleeve to force the mechanism upward.

Most manual jacks are what you might call “hand pump.” Using the handle, you pump the hydraulic shaft full of air, and it pushes out the rod assembly, raising the jack. Most domestic floor or bottle jacks require more pumps to get the car into the air. However, NASCAR jacks are tuned to lift the entire side of the car in one to two pumps.

Others use air power from a compressor, but the end result is the same. The big difference is the lift capacity of the jack. The more weight to be lifted, the more likely you will need one that will require compressed air to activate it. Shops that lift 25-ton semi-trailers to change a tire need a heavy-duty compressor to operate the jack properly and efficiently.

Conclusion

Knowing what you need your next jack for is the first step. When choosing yours, or one for someone else, remember that it is an investment. Properly maintained, a jack can last decades. So, if there is one that is higher quality but also has a higher sticker price, just for the longevity of the jack, it is worth it to get the better one.

There are many brands, styles, and even colors, so do your research. There are three common types of car jacks on their own. Read reviews, talk to people in the industry that use the jack you are looking at, and get the inside scoop. If you have ever used a cheaper or poorly constructed jack, you know how important it is to get the right one. It is as much about safety as it is price.

Contents